When you consider gearbox design, energy efficiency shouldn’t just be an afterthought; it’s essential. By focusing on reducing energy losses, you not only improve performance but also cut operational costs and support sustainability efforts. As industries evolve, the demand for more efficient gearboxes grows, pushing you to rethink design strategies and embrace new technologies. But what specific innovations are paving the way for this efficiency, and how can they impact your operations?

Understanding Energy Efficiency

Energy efficiency is crucial in today’s gearbox design, affecting not only performance but also sustainability. When you consider energy efficiency, you’re really looking at how effectively a gearbox converts input power into output power without excessive losses. These losses often stem from friction, heat generation, and other inefficiencies that can seriously impact overall performance.

To understand energy efficiency, you need to focus on several key factors. First, the materials used in gearbox construction play a significant role; high-quality materials can minimize wear and tear, reducing energy losses.

Next, the design and manufacturing processes must optimize gear shapes and alignments to ensure smooth operation. You’ll also want to pay attention to lubrication methods, as proper lubrication can drastically cut down on friction.

Moreover, you should be aware that energy efficiency isn’t just a technical specification; it’s a mindset that integrates performance goals with environmental responsibility. By prioritizing energy-efficient designs, you’re not only enhancing the gearbox’s operational lifespan but also contributing to a more sustainable future.

Keep these aspects in mind, and you’ll gain a clearer picture of what energy efficiency truly means in gearbox design.

Key Benefits of Energy-Efficient Gearboxes

A well-designed energy-efficient gearbox offers numerous advantages that can significantly enhance your operations. First, these gearboxes reduce energy consumption, which translates to lower utility bills. By minimizing energy waste, you not only save money but also contribute to a more sustainable environment.

Additionally, energy-efficient gearboxes often lead to improved performance. With less energy lost in the system, you’ll experience smoother operation and increased reliability. This efficiency can result in longer equipment life, reducing the frequency of repairs and replacements, which further saves you time and costs.

Moreover, when you invest in energy-efficient gearboxes, you enhance your company’s reputation. Many clients and partners prioritize sustainability, and demonstrating your commitment to energy efficiency can set you apart from competitors.

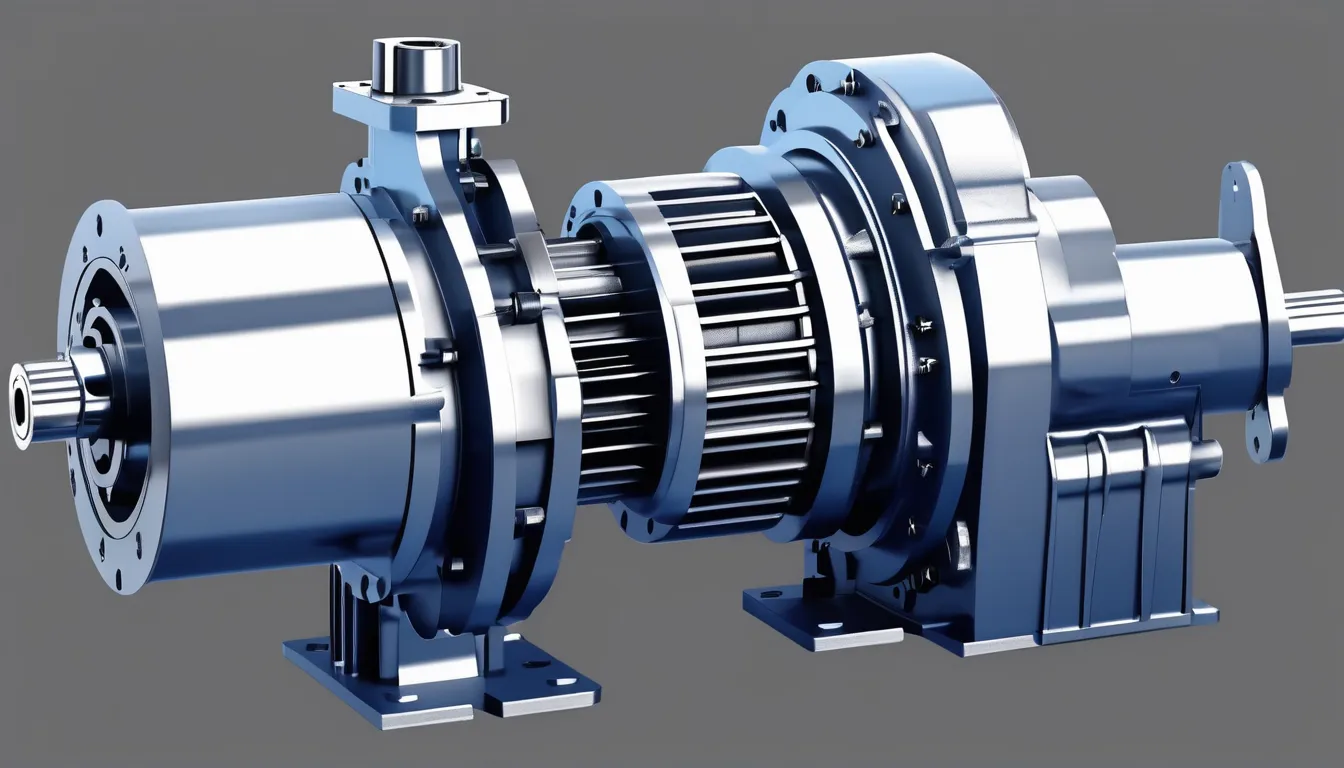

Design Considerations for Efficiency

When designing a gearbox for efficiency, several key factors come into play that can significantly impact performance. First, you’ll want to consider the gear ratio. Selecting the right ratio helps optimize torque and speed, reducing energy losses.

Next, pay attention to the materials you use; lightweight, high-strength materials can minimize weight while maintaining durability, enhancing overall efficiency.

Bearings and lubrication are also critical. Using high-quality bearings reduces friction, and choosing the right lubricant ensures smooth operation, lowering energy losses. Additionally, avoid unnecessary complexity in your design. A simpler gearbox with fewer components can lead to reduced friction and maintenance issues, ultimately improving efficiency.

Lastly, think about thermal management. Excess heat can waste energy, so incorporating features that aid in heat dissipation can keep your gearbox running efficiently.

Technological Innovations in Gearbox Design

Innovations in gearbox design are revolutionizing how we approach efficiency and performance. As you dive into the latest advancements, you’ll notice how these technological strides directly impact energy consumption and operational effectiveness.

Here are four key innovations shaping the industry:

- Advanced Materials: Using lightweight and high-strength materials reduces weight while enhancing durability, promoting better energy efficiency.

- Smart Sensors: Integrating IoT devices and sensors allows real-time monitoring of gearbox performance, enabling predictive maintenance and reducing downtime.

- Optimized Gear Geometry: Innovative gear profiles minimize friction and improve load distribution, leading to lower energy losses during operation.

- Modular Designs: Modular gearboxes enable easy customization and adaptability, allowing you to tailor solutions to specific applications without extensive redesign.

These advancements not only enhance the lifespan and reliability of gearboxes but also significantly contribute to overall energy efficiency.

Future Trends in Energy Efficiency

As advancements in gearbox design pave the way for greater energy efficiency, it’s clear that the future holds even more promising trends.

You’ll likely see a shift toward smart gearboxes equipped with IoT technology. These smart systems can monitor performance in real-time, allowing for immediate adjustments that enhance efficiency and reduce energy waste.

Another trend is the integration of advanced materials. Lightweight composites and high-strength alloys can minimize weight while maximizing durability, leading to less energy consumption during operation.

You’ll also encounter more emphasis on modular designs, allowing for easier upgrades and repairs, which can extend the lifespan of china Custom gear solutions es and improve overall efficiency.

Moreover, expect an increase in the use of simulation software during the design phase. By utilizing advanced modeling, engineers can predict performance and optimize designs before production begins, resulting in more efficient gearboxes right from the start.

Conclusion

In conclusion, prioritizing energy efficiency in gearbox design isn’t just smart—it’s essential. By embracing innovative technologies and advanced materials, you can significantly reduce operational costs and enhance performance while contributing to a more sustainable future. As industries shift towards eco-friendly practices, your commitment to energy-efficient gearboxes will not only improve reliability and lifespan but also align with broader environmental goals. Together, let’s drive towards a more efficient and sustainable tomorrow.