In industrial settings, safety is dominant, especially when workers are unclothed to wild environments. Toxic gases, flammable vapours, and oxygen-deficient atmospheres can pose terrible risks. To mitigate these dangers, gas detectors and analyzers play a material role in ensuring work refuge. These devices not only protect employees but also help companies comply with safety regulations.

Understanding the Risks

Industries such as oil and gas, chemical manufacturing, and run off direction frequently encounter wild gases. Exposure to substances like carbon paper monoxide, H sulfide, or inconstant organic compounds can lead to ague health issues or long-term prolonged conditions. Moreover, flammable gases can light, leading to explosions and catastrophic incidents. Therefore, early detection and monitoring of these gases are vital.

The Role of Gas Detectors

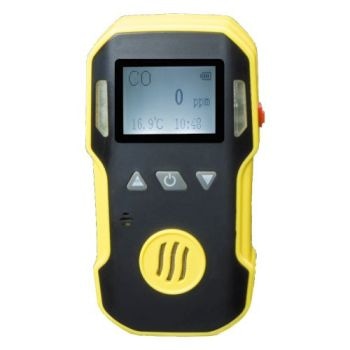

voc analyzer s are specialised instruments designed to identify the front of particular gases in the environment. They come in various types, including outboard and rigid detectors. Portable detectors are often used by workers who need real-time feedback as they move through potentially dangerous areas. Fixed detectors, on the other hand, are strategically placed throughout facilities to continuously ride herd on air timbre.

These devices work on different principles, such as chemical science, infrared emission, and chemical process sensors. Electrochemical sensors are unremarkably used for detection nephrotoxic gases. Infrared sensors are nonesuch for measurement hydrocarbons, while chemical action sensors surpass at detecting inflammable gases. By selecting the appropriate engineering, companies can check correct readings plain to their specific environments.

Gas Analyzers: A Comprehensive Approach

While gas detectors cater real-time alerts, gas analyzers offer a more in-depth psychoanalysis of air tone. These can quantify septuple gas concentrations at the same time, providing a comprehensive view of the atm. Gas analyzers are particularly useful during sustentation checks or reply scenarios, allowing refuge staff office to sympathize the of a unsafe state of affairs.

Moreover, advanced gas analyzers can to web systems for data logging and coverage. This boast enables companies to get across existent trends in air timbre, helping them identify recurring issues and follow out preventative measures.

Integrating Safety Protocols

To maximise the effectiveness of gas detectors and analyzers, they must be integrated into a comp refuge protocol. Training employees on the correct use of these devices is material. Workers should empathize how to understand readings and react fitly to alerts. Regular sustainment and standardisation of the equipment are also requirement to insure reliability and truth.

Incorporating gas detection systems into the readiness plan enhances refuge further. By establishing monitoring points in high-risk areas and ensuring that alarms are clunky and ocular, companies can create an environment that prioritizes prole refuge.

Regulatory Compliance

Many industries are subject to demanding refuge regulations set by organizations like OSHA(Occupational Safety and Health Administration) and NFPA(National Fire Protection Association). Compliance with these regulations often necessitates the use of gas signal detection and monitoring systems. Investing in these technologies not only protects employees but also helps companies avoid potential fines and legal repercussions.

Conclusion

In hazardous heavy-duty environments, the use of gas detectors and analyzers is not just a refuge quantify; it is a critical component part of an operational safety communications protocol. By ensuring real-time monitoring and comprehensive examination air quality psychoanalysis, these devices protect workers from the dangers of cyanogenic and flammable gases. Companies that prioritise gas signal detection technology not only heighten work safety but also present a to regulative compliance and employee well-being. As industries evolve, the integrating of sophisticated gas monitoring solutions will continue to be a of heavy-duty refuge.